Ensuring Tablet Integrity with Precision and Compliance

Tablet Hardness Test

About Us

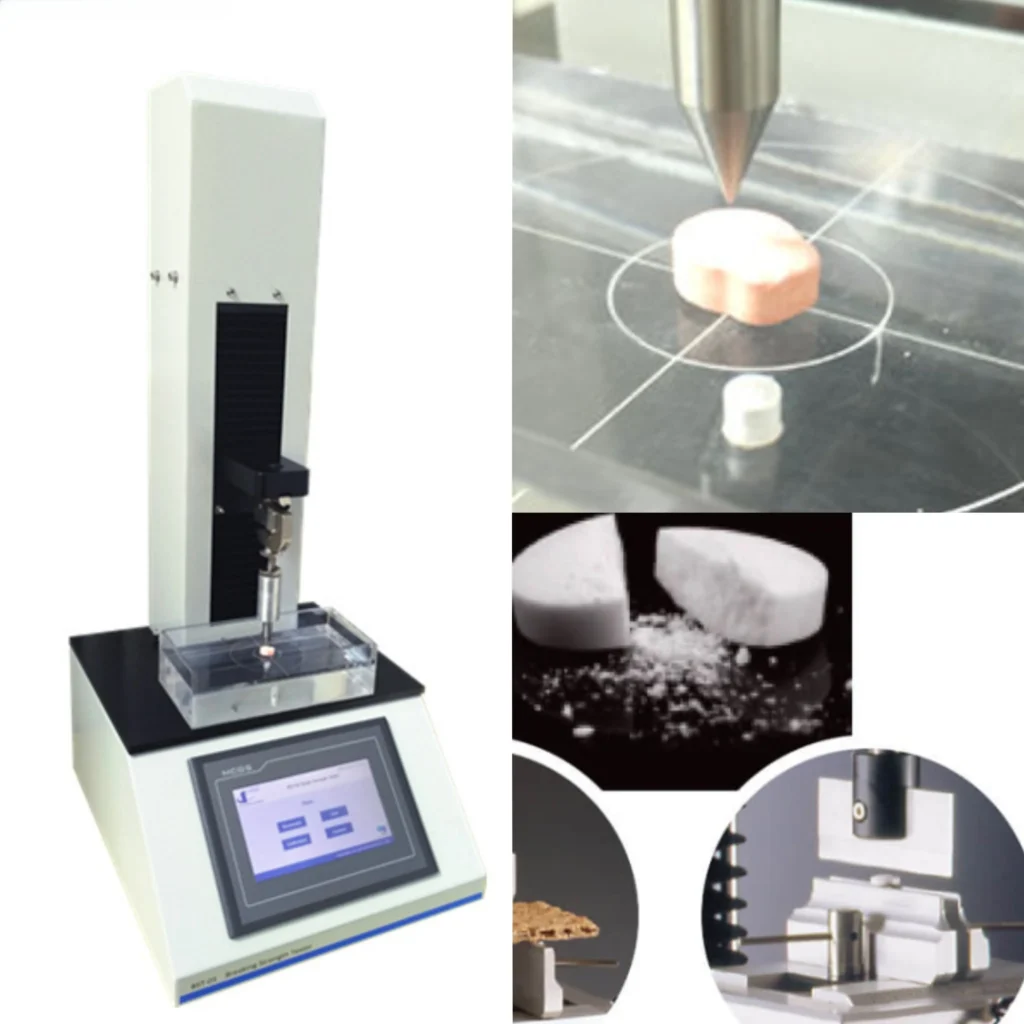

Introduction to Tablet Hardness Tester

The Tablet Hardness Tester is a specialized instrument designed to measure the mechanical strength of pharmaceutical tablets. It evaluates how much force a tablet can withstand before it breaks, helping manufacturers ensure that each dose maintains its shape and performance from production to patient delivery.

In pharmaceutical manufacturing, improper tablet hardness can lead to issues like crumbling during packaging or overly hard tablets that don’t disintegrate properly in the body—both of which affect drug efficacy and safety. This is why tablet hardness testing is a critical step in pharmaceutical quality control.

Cell Instruments provides advanced tablet hardness testers

Main Functions and Advantages of the Product

These features make it ideal for both quality control and formulation development.

Main Functions and Advantages of the Product

Cell Instruments' tablet hardness tester is engineered for accuracy, compliance, and ease of use, offering key features and advantages.

High-precision loadcell for accurate force measurements (±0.5% F.S.)

7-inch touchscreen (HMI) for easy operation

PLC-controlled system for industrial-grade stability

Adjustable test speed to fit different tablet types

Real-time data display of force and displacement

Automatic return, limit protection, and easy calibration

Microprinter and RS232 output for documentation and traceability

Optional software for data analysis and storage

Multiple fixtures for various tablet shapes and sizes

Test Method Overview

Standard Reference:

The test procedure aligns with USP – Tablet Breaking Force, which provides guidelines on: Loading rate (≤ 3.5 mm/s or ≤ 20 N/s) Sample orientation Calibration requirements Valid sample size (minimum 6 tablets)

How does it work?

During the test, the tablet is positioned between two platens. The upper platen applies a controlled force vertically until the tablet fractures. The breaking force (in Newtons) is recorded to assess tablet hardness.

Technical Parameter Table

| Test Range | 200N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |

Applicable Fields and Typical Applications

tablet hardness test

- This equipment is widely used in:

- Pharmaceutical production and batch release

- Research and development labs

- Generic drug manufacturing

- Bioequivalence studies

- GMP-compliant QC laboratories

- Tablet formulation optimization

- Typical applications include:

- Testing tablet strength during development

- Checking batch consistency

- Comparing coated vs uncoated tablet performance

- Ensuring packaging integrity

- Studying the effects of moisture or storage on hardness

tablet hardness test

Importance of Tablet Hardness Testing

01

Importance of Tablet Hardness Testing

Assures drug delivery performance (proper disintegration & dissolution)

Improves product durability for transport and handling

Reduces batch variability

Supports regulatory compliance

Enhances patient experience and trust

02

Company Advantages

🏭 Professional Manufacturer: Specialized in precision materials testing instruments for over a decade

🔧 Customization Capabilities: Tailored solutions for special shapes, high-force testing, or integration into automation systems

🌍 Global Support: Products are used in over 50 countries by labs, manufacturers, and inspection bodies

📦 Comprehensive After-sales Service: Installation guidance, remote training, calibration support, and rapid response

"The Tablet Hardness Tester from Cell Instruments ensures reliable, accurate, and standardized testing that aligns with international pharmacopoeias like USP ."

efficiency, compliance, and confidence

Frequently Asked Questions (FAQ)

📩 Contact us today to learn more or request a quote tailored to your testing needs.

Q1: How many tablets are required per test?

A: According to USP <1217>, at least 6 tablets should be tested to ensure accurate and statistically meaningful results.

Q2: Can I test scored or coated tablets?

A: Yes. The tester supports multiple fixtures and orientation methods, suitable for scored, coated, chewable, and irregular tablets.

Q3: What’s the difference between hardness and friability?

A: Hardness measures a tablet’s resistance to breaking under pressure, while friability tests how well a tablet resists surface abrasion.

Q4: Is calibration required regularly?

A: Yes. For compliant testing, periodic calibration is required using certified reference weights or load cells.

Q5: Can your system connect to LIMS or export data?

A: Yes. Our testers offer RS232 output, optional software, and support for integration with data management systems.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985